Project Info

OVERVIEW

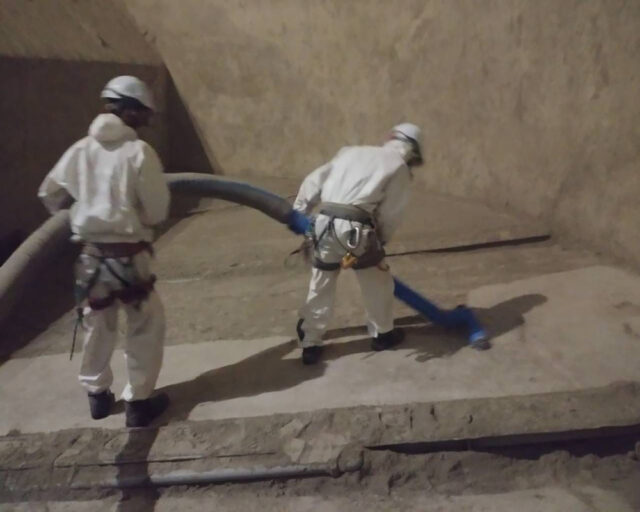

Talos Industrial Services has implement activities with mobile Vacuum Truck for the collection of dry material from the facilities of the Cement Factories We are currently assisting in the Factories production problems regarding Silos Storages with Cleaning & removing the Deposit materials with our OWN Mobile Vacuum when the Silos Discharge system was out of order and when they are spillages and waste material so they can be retrieved and Feed them back to the production.

1. ADVANTAGES OF USING A VACUUM CLEANING SYSTEM / MACHINE

Easy cleaning of the production areas with consequent improvement

of the environment.

- Less risk of accidents at work and risks of diseases caused by the

presence of dust. - Reduction of time and costs for maintenance on the production lines.

- Reduction of the stop of production and improved quality of final

products.

2. RECOVERY SAVINGS CALCULATION

We estimate that in a medium size cement plant, almost more than 20 40 ton of raw materials and final product are continuously lost along production lines every day of production (conveyor belts, elevators, filters, mills). If not quickly recovered, these materials must be wasted.

The vacuum system (fixed or mobile) allows to easily recover the spillages and feed back the materials. With consequent savings on the cement production lines (recovery).

Estimated Local Market price per tonn of Cement = 120,00 USD

Minimum Savings = 20 tonns X 120 USD = 2.400 USD / day X 300 production days = 720.000 USD / year.

- Average Savings =40 tonns X 120 USD = 4.800 USD / day X 300 production days = 1.440.000 USD / year.

Moreover, occasional and unexpected spillages can always append and vacuum equipment is the solution to the problem.

3. STOP OF PRODUCTION

Cement plant are subject to several stops of production per year caused by spillages or Silos blockage.

Production lines are accumulating the spillages day by day until they brake down and cause the stop of production. The vacuum system (fixed or mobile) allows to keep production lines clean and assist in the Silos cleaning procedure with vacuum the material if the discharge system is not working.

A production line clean will not damage the components and some stops of

production will be avoided and the factory will use its full capacity regarding the silos.

4. MAINTENANCE COST

Vacuum system (fixed or mobile) allows to keep production lines clean.

A production line clean will have less abrasion on the components installed and provide longer life for them. Reduces the cost of spare parts for normal maintenance service in the factory. These are indirect costs but quite big amount if calculated at the end of the year.

5. SAFETY & ENVIRONMENTAL COSTS

Vacuum system (fixed or mobile) allows to keep the working environment clean and reduce the worker diseases consequence of continuously breathing the fine dust.

It also reduces the risks of accidents and keeps the surrounding area with less of flying dust cement particles and help regarding the environmental issues.

All these are indirect costs difficult to calculate but always on the higher side.